It seems everyone has a theory on why Rhode Island’s economy stinks. Now the Boston Fed has one too.

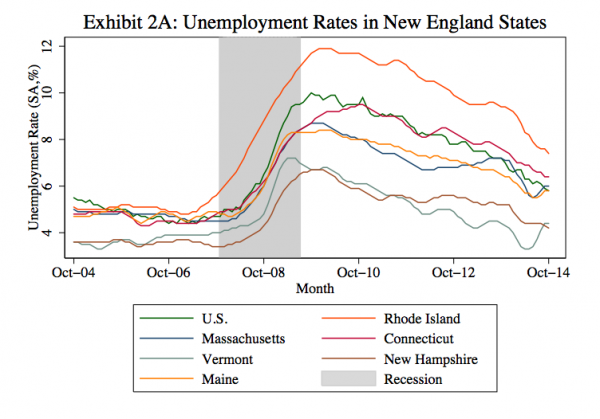

“This paper seeks to discover why Rhode Island experienced a more severe downturn during the Great Recession than any other New England state and why it continues to lag other states in the region and the nation as a whole in some measures of labor market health,” writes senior economist for the Federal Reserve Bank of Boston Mary A. Burke.

“The three sectors that contributed most to Rhode Island’s poor relative performance in the region were finance, government, and manufacturing, in that order,” Burke writes. “Had Rhode Island performed only as poorly in each of these latter three sectors as Connecticut, the second-worst-performing state in the region, virtually all of the difference … between Rhode Island and Connecticut in terms of peak-to-trough percentage job losses would have been eliminated.”

It’s well-known that Governor Don Carcieri shrank state government right before the crash. Burke says this didn’t help.

“Rhode Island experienced significantly slower growth in government spending than any other state in the region,” she wrote. “And, over the entire period, Rhode Island had the second-lowest cumulative growth rate in government spending in the region, beating out Maine by only a very small margin. Furthermore, prior to the recession, government spending represented a relatively large share of Rhode Island’s gross state product.”

Like most who muse over this question, Burke cites the loss of manufacturing jobs as a contributing factor – though she says globalization was already doing a number on that sector. “The state’s steep manufacturing losses most likely contained a large structural component that was already in force prior to the recession.”

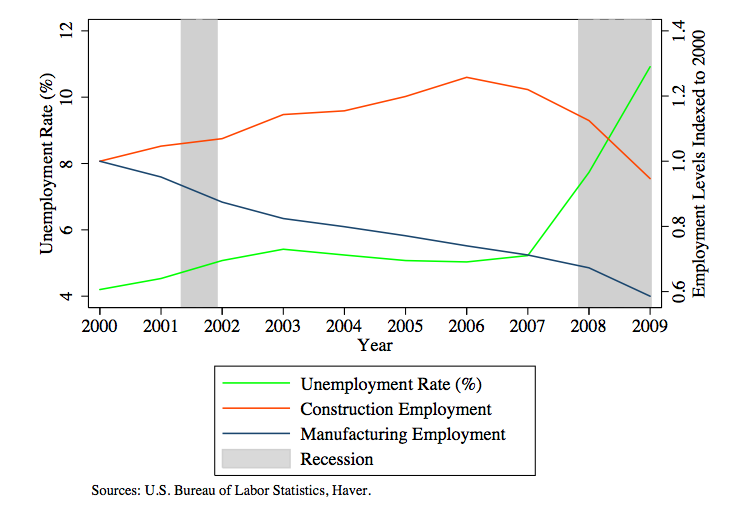

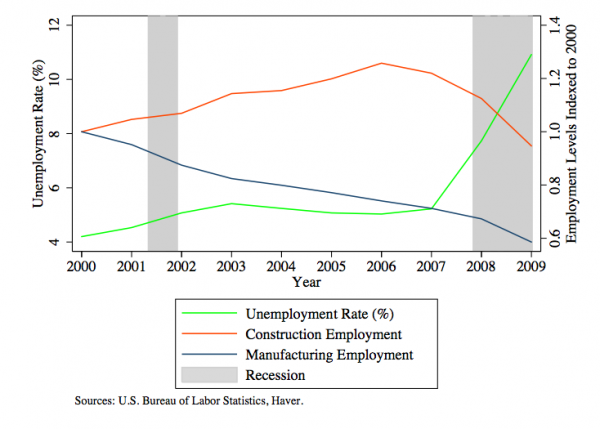

You can see in this chart that unemployment was somewhat steady as manufacturing was steadily dipping, and that unemployment spiked when construction sank.

But there was something to Rhode Island’s relatively uneducated manufacturing sector that didn’t bode well for them when the recession hit.

But there was something to Rhode Island’s relatively uneducated manufacturing sector that didn’t bode well for them when the recession hit.

“…Rhode Island had by far the highest pre-recession concentration of high-school dropouts in its manufacturing sector among the New England states,” Burke writes. “At the national level, high school dropouts in manufacturing were not especially vulnerable to job losses as compared with other manufacturing employees. Therefore, Rhode Island’s high concentration of dropouts in manufacturing, all else being equal, would not have predicted an excess of total manufacturing job losses. However, high school dropouts in Rhode Island’s manufacturing sector experienced job losses in the recession at a rate close to three times the national rate and contributed a full one-third of Rhode Island’s manufacturing job losses, a larger share than in any other New England state.”

Of course, globalization, shrinking government, and a poorly-educated workforce didn’t cause the Great Recession all by themselves. “…the housing bust was stronger in Rhode Island than in any other New England state except Connecticut,” writes Burke.

And the housing bubble, which precluded and ultimately led to the housing burst, was doing a fairly decent job of hiding the damage done to the state’s economy from the flight of manufacturing. When the construction workers started looking for new jobs, things got real bad for the manufacturing workers.

“Once construction activity began to plummet in Rhode Island, displaced manufacturing workers had far worse re-employment prospects than during the construction boom,” she writes.

That was then. Burke says there’s now some reason for optimism. Though I’m inherently skeptical of anything that takes this level of economist-speak to explain. She writes,

“If we compute the fraction of total employment losses (peak-to-trough) that have since been recovered — by taking the difference between the peak-to-trough percentage change in employment and the peak-to-current percentage change inemployment and dividing this difference by the peak-to-trough percentage change — Rhode Island ranks last in the region. However, in terms of jobs recovered since the trough in terms of raw percentage points in relation to the pre-recession peak employment level in a given state — which is the absolute value of the raw difference described in the preceding sentence — Rhode Island ranks second-best.”

In layman’s terms, you can crunch the numbers both ways. But what’s interesting is the report indicates that while the Providence metro area (from roughly Warwick to Fall River) helped the state as a whole fall into the recession, it hasn’t been helping it climb out.

“Providence also places second-last (again behind Norwich) in terms of trough-to-current employment change, even though Rhode Island placed second-best on this score among New England states. Since the trough, then, Rhode Island’s relatively strong performance belies the relative performance of the Providence” area.